Under the motto “Be pro”, Schwäbische Werkzeugmaschinen GmbH (SW) will be presenting two machining centers at this year’s EMO with which users can significantly increase their productivity: the new BA W08-12 machining center with a large work envelope for structural components and the BA 322i with loading module, designed as a self-sufficient cell.

Almost all automakers have entered series production of electrified vehicles and are using large-format structural components made of light metals to further reduce weight. “The single-spindle BA W08-12 is specially designed for machining large components,” emphasizes Reiner Fries, Managing Director Sales at SW. “It, like the other SW linear motor machines, achieves higher dynamics than most competitive machines, directly increasing productivity.” The BA W08-12 provides a working area of 1,500x900x650 mm for 4- and 5-axis machining.

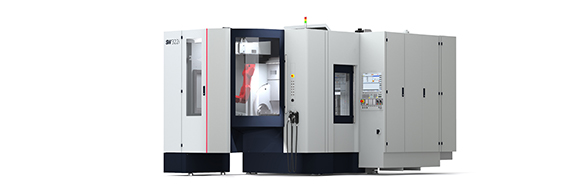

Be productive: BA 322i fully automated manufacturing cell for unmanned shifts

Two-spindle machining centers double output with a smaller footprint and less energy consumption. In the fully automated, stand-alone BA 322i production cell, the loading module with integrated 6-axis robot and pallet storage is already mounted on the machine. “The accumulator is sufficient for completely unmanned shifts, but can also be refilled at any time without stopping the machine,” explains Reiner Fries. With a spindle distance of 300 mm, the working area measures 300 x 450 x 375 mm. Automotive suppliers or users from the medical technology and precision mechanics sectors thus significantly reduce the unit costs of production.

Be proactive: SW algorithms incorporate the experience of millions of hours of operation

“We have been networking our machines at customers’ sites for years, and have created a SW cloud platform with high security standards. I would like to see even more users put aside their fears and use the data to achieve and maintain maximum productivity throughout the entire lifecycle,” emphasizes the SW CEO. “As one of the six building blocks of the life Services portfolio of services, we use life data to record operating data, as well as condition and maintenance information for customers. The encrypted data is also sent only to where the customer wants it.” Based on several million hours of operation, SW has developed algorithms that make process improvements possible in the first place. “With condition monitoring capabilities, we enable predictive maintenance that saves time and money.”

Retrofits for such functionalities can partly be performed by customers themselves or are supported by the life Upgrade team. All the building blocks of SW life Services are interlinked in such a way that they ensure optimum support for SW machines over their entire life cycle and always offer potential for optimization.

SW at EMO: Hall 12, Booth C58

You will also receive the appropriate image material for our press releases. Please contact us if you are interested.