The SW machine portfolio:

Consistently productive and precise

Our machining centers set standards in the economical and precise machining of steel, cast iron and non-ferrous metals. SW CNC machines are finely scalable in terms of workspace size, cutting material and number of spindles with the same operation and cover a wide range of workpieces. As crane hook machines, they save installation space and shorten (re)start-up times.

Constructive

precision

Proven design principles such as monoblock and the box-in-box 3-axis unit ensure maximum rigidity and machining precision. The double swivel carrier for loading and unloading during machining reduces unproductive downtime. This enables you to produce series components for wheel suspension and steering, brakes or transmission components with the highest precision and efficiency, as well as implants for medical technology.

Direct drive for shortest machining times

Our portfolio covers your exact requirements. The CNC machining centers for light metal machining are the fastest on the market thanks to linear motor technology. This technology is the fastest on the market, which enables you to achieve maximum productivity in machining, whether for ABS blocks, engine housings or large structural components for electric vehicles.

for every quantity –

The most economical solution

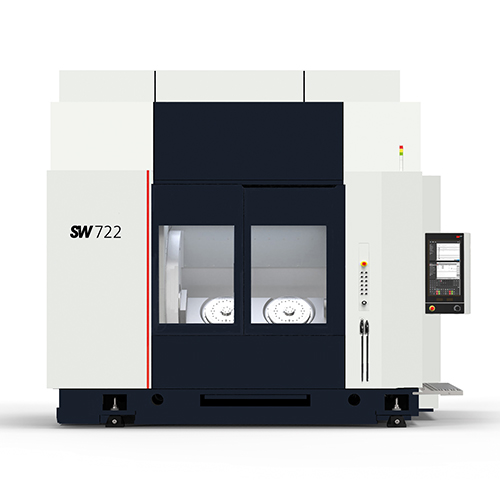

Whether customers require single-spindle or multi-spindle CNC machining centers, SW always offers you the most economical solution for your production volumes. For medium and large series production, for example, our multi-spindle CNC machining centers show their strengths: Four-spindles reduce cycle times by up to 60 percent compared to four single-spindles. And they do so on 70 percent less floor space. For each application we also offer you the matching automation for single machines, independent cells, or complete production lines.

SW machines create more

with less energy

The best contribution to climate protection is greater energy efficiency in production, because it reduces CO2 emissions and lowers operating costs. SW machines are setting new standards. Our four-spindle machining centers consume only about half the energy of four single-spindle machines. And they do so at a higher output.

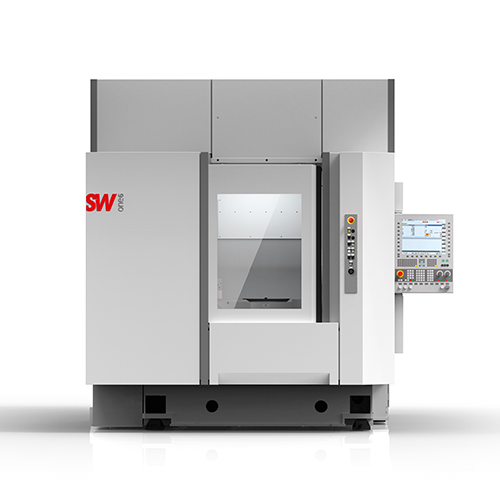

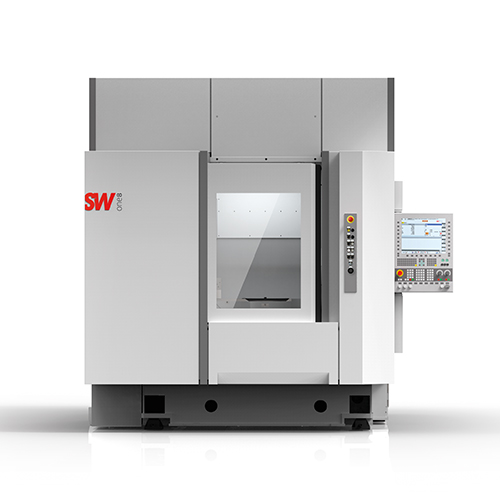

Many machines, one family

No matter whether you choose a single-spindle or multi-spindle machine, whether you machine light metal or cast iron, whether your workpieces are small or large, SW machines follow the same design principles and operating philosophy. That’s why your operators and maintenance staff will immediately become familiar with machines from SW, ultimately utilizing the full productivity potential.

Machine nomenclature

BA W06-22

| BA | Machining center |

| W0 | Linear drive |

| 6 |

Size 6 – standard spindle distance (600 mm) |

| 2 | Number of spindles |

| 2 | Number of work tables |

BA 322i

| BA | Machining center |

| 3 |

Size 3 – standard spindle distance (300 mm) |

| 2 |

Number of spindles |

| 2 | Number of work tables |

| i | Integrated automation |

Technology at SW

Cutting performance and surface quality are dependent on the manufacturing tools, the clamping devices, and the automation program. Our Technology People support you with their decades of experience to achieve the maximum output with your CNC machining centers.