A FUTURE WITH SYSTEMS:

Customized manufacturing solutions from a single source

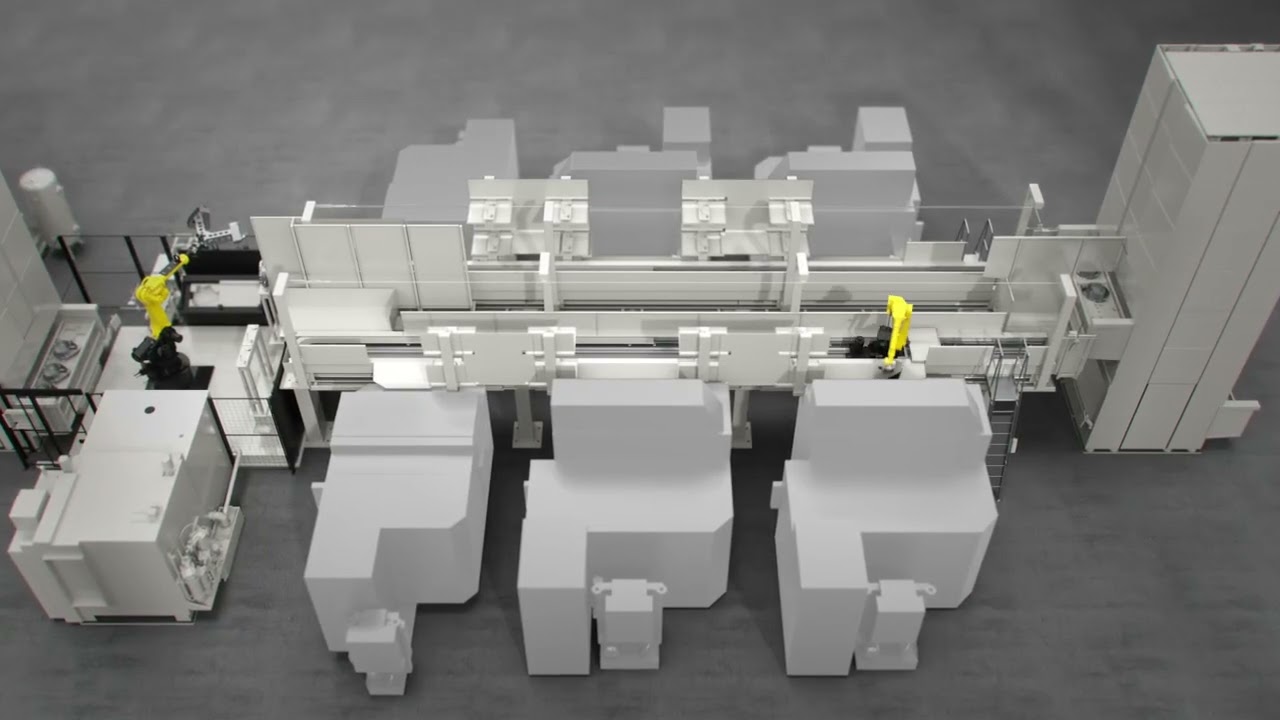

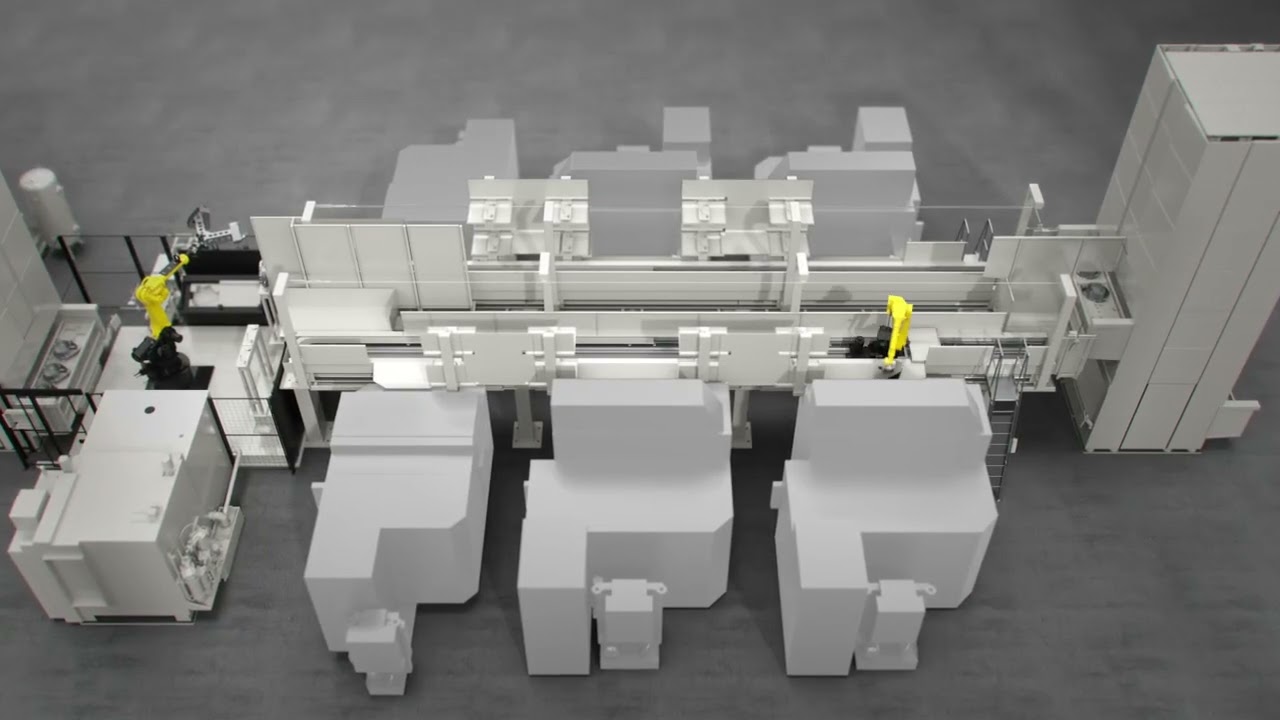

From the raw part to the packaged and ready-to-ship component, we plan and implement complete production lines for you. These lines are precisely matched to your components and the planned quantities. This results in a customized manufacturing solution from a single source – more security, fewer project risks.

Technology People have already developed numerous manufacturing solutions for the large-scale production of a component family and production with a wide range of variants is realized. Our systems are designed to be complete. This begins with single and multi-spindle CNC machining centers with automatic loading and unloading. This also includes fixture changes and peripheral processes such as brushing, cleaning, drying, assembling, leak testing, preserving, and packaging. SW links all process steps in a coherent manufacturing solution with end-to-end automation.

One contact person from simulation to ramp-up of quantities

We use the latest simulation methods for fact-based consulting. As early as the planning phase, we can provide you with the information you need to calculate your workpiece costs. This gives you resilient return-on-investment values for your investment. We define the optimal floor layout and take over the cycle time design. We link the CNC machining centers with intelligent automation solutions from a modular system and take care of the material flow analysis.

The manufacturing solutions are highly automated for the shortest lead times. In this way, you reduce your personnel costs and achieve the highest quality in a reproducible manner. We also coordinate all tasks during commissioning and accompany you from start of production to the ramp-up of quantities.

Fits perfectly into your IT landscape

The manufacturing solutions from SW fit seamlessly into your IT landscape. Whether you choose an MES system from SW or prefer your own solution, you always have complete traceability of all process steps and an overview of all operating data for continuous improvement of your production via the IDS interface. SW manufacturing solutions also use data interfaces to tap into the sustainable potential of the Industrial Internet of Things (IIoT) and Industry 4.0.

learn more about custom manufacturing solutions from sw:

Connection.

Contact us to learn more about automation systems: